12V 6Ah Lithium ion Battery Lifepo4 Battery

12V 10Ah Lithium ion Battery Lifepo4 Batteries

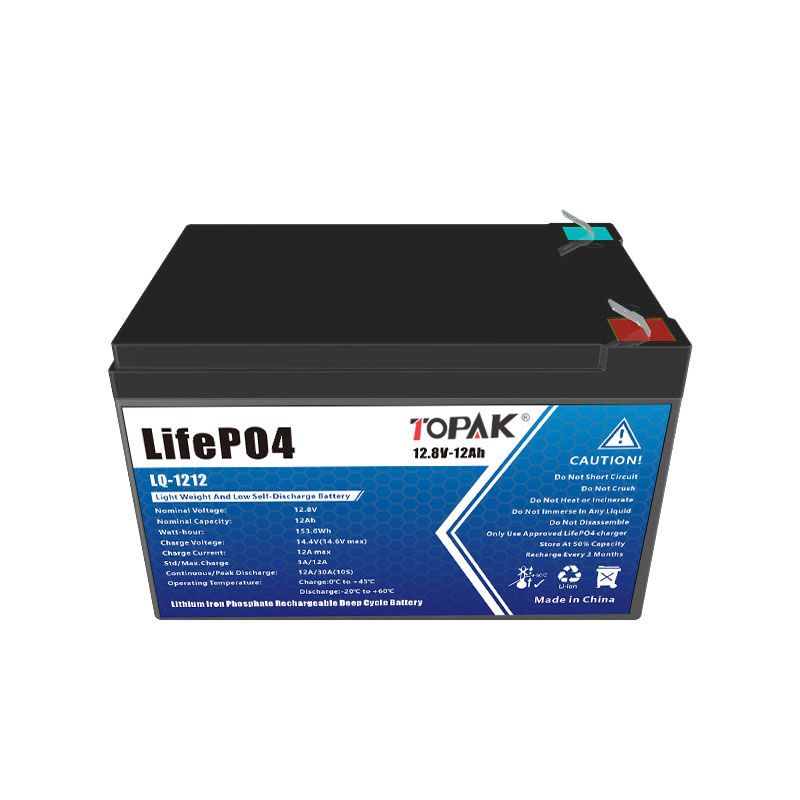

12V 12Ah LiFePO4 Lithium Iron Phosphate Battery

12V 18Ah Lifepo4 Lithium Battery Cell

12V 20Ah replacement Lead acid Lithium Battery

12V 36Ah Lithium Iron Phosphate Battery

24V 50Ah Lifepo4 Battery Lithium ion Battery

24V 100Ah lifepo4 iron batteries replacement lead acid lithium battery

24V 200Ah lifepo4 battery replacement Lead acid Lithium Battery

48V 50Ah Lithium Iron Phosphate Battery replacement Lead acid Lithium Battery

48V 100Ah lithium batteries replacement lead acid lithium battery

TOPAK 51.2V 300AH Vertical Home Energy Storage Battery

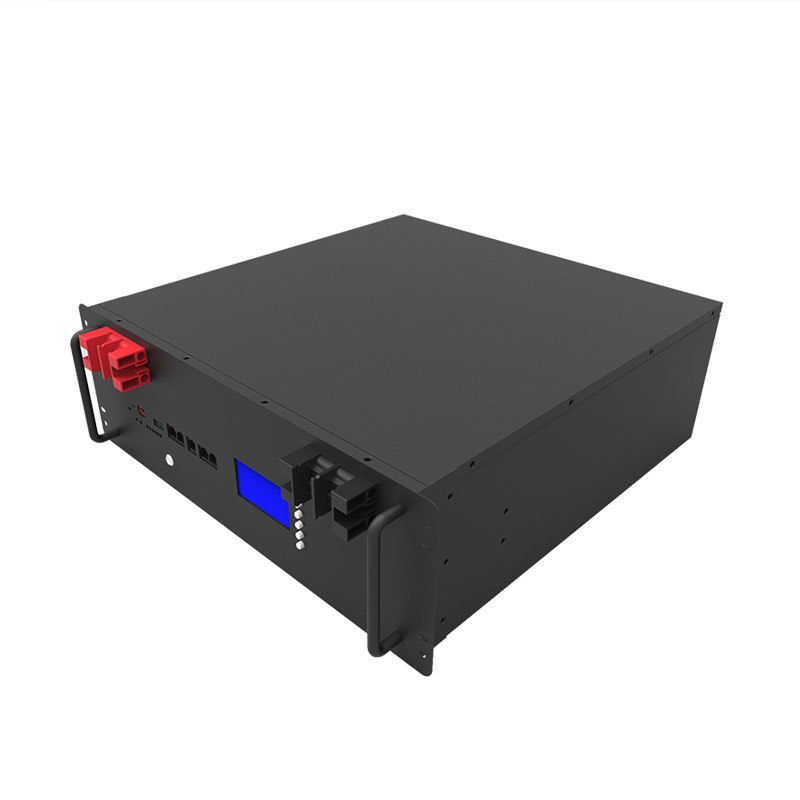

TOPAK 48V 100Ah Home Rack Mounted Energy Storage Batteries

TOPAK 51.2V 100Ah Stackable Battery Shunt able Solar Battery

TOPAK 24V 200Ah Solar Household Wall mounted Battery

48V 1000Ah household Photovoltaic energy storage split type machine

TOPAK 5KWA+5KWh Vertical Home Solar Inverter Energy Storage Integrated Machine Parallelable

384V 100Ah Backup power supply 38.4kWh UPS Data Center Power System

384V 50Ah Backup power supply 19.2kWh UPS Data Center Power System

192V 100Ah Backup power supply 19.2kWh UPS Data Center Power System

192V 50Ah Backup power supply 9.6kWh UPS Data Center Power System

224V 100Ah UPS Power System 22.4kW LiFePO4 Battery System

TOPAK 224V 30Ah Lithium ion UPS lifepo4 Battery 6.7KW UPS Backup

48V 150Ah tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

48V 100Ah(5U) tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

Topak tower energy stroage battery for backup power supply,home/hopital/bank/small business/base station use

Topak 48V 100Ah Lithium ion battery BMS Solar Energy Storage System Lifepo4 Battery

48V 200Ah tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

48V 100Ah(4U) tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

12V 100Ah Lifepo4 Battery Patent design lithium battery

TOPAK RV Lifepo4 Battery 12V 400ah Energy Storage Lithium iron Phosphate RV Battery

51.2V20AH Lithium battery for electric bicycle battery converter

10.8V2.1AH Massager lithium battery

29.6V7.5AH Reserve power supply lithium battery

64V100Ah electric tricycle lithium battery

Writer: TOPAKRelease time: 2019-06-12Page View: 3076

China’s electric bicycle ownership reached 150 million units, most of the waste batteries flow to small workshops

Recently, the vice president of Jiangsu Chunxing Alloy Group Ma Yonggang is very worried, the company as the largest producer of recycled lead, is not collected enough waste lead-acid batteries.

“Our factory in Pizhou, 2 mechanized automatic crushing and sorting production lines with international advanced level, can handle more than 2,000 tons of waste lead-acid batteries per day, the second phase will plan 4 production lines, according to the existing recycling volume is definitely ‘not enough’.” Ma Yonggang said helplessly.

Open the “National List of Hazardous Waste”, 49 categories of hazardous waste, lead-acid batteries are among them. How it is harmless treatment, both to avoid waste of resources and to prevent secondary pollution, which is the production of electric vehicles in Jiangsu province, is a realistic topic can not be avoided.

Where do all the old batteries go?

Motivated by profit, most of them are resold to workshops.

“It saves energy, it’s convenient, and the key is not to get stuck in traffic.” Speaking of the benefits of electric bicycles, Ms. Wang, a citizen of Nanjing, came out of the blue. “The downside is that you often have to change the battery, which no, it’s been changed twice.” Ms. Wang said the battery can’t be charged, so she can only go to the original point of sale to exchange the old for the new.

The reporter investigation found that the vehicle sales, maintenance point is the waste lead-acid battery recycling chain on the “first drop point”. So, these are concentrated waste batteries and flow to where? “70% to 80% were resold to hawkers.” Ma Yonggang introduction, to a weight of about 15 kilograms of electric bicycle battery for example, general lead content in about 63%, pure lead weight of about 9.5 kg, a resale can be sold for one hundred and eighty yuan. At present, the price of pure lead on the market is as high as 16,500 yuan / ton, leading to “snatchers” scrambling.

Jiangsu is lead-acid battery production, processing large province, the annual national scrap of lead-acid batteries in 2 million tons, 1 / 4 in Jiangsu processing. 2011 June, the Jiangsu provincial environmental protection department to launch a special remediation, all the province’s lead-related enterprises to dragnet inspection, shut down a number of illegal disposal of enterprises. However, the current clandestine activities of the “guerrilla” is still a minority.

Solid waste center of Jiangsu Province Environmental Protection Department, hazardous waste management section chief Chen Feng told reporters, prior to China’s hazardous waste management involves only waste batteries “disposal” of a ring, and “recycling” has been at the edge of the law, until 2011, the Ministry of Environmental Protection a document put forward “For units engaged in the collection and storage of hazardous waste, such as waste lead-acid batteries, the approval of hazardous waste business licenses will be carried out in accordance with the law.” At present, however, a wide range of small recycling workshops are still not under actual jurisdiction.

Who should pay for environmental responsibility?

The price of the “regular army” is the main reason why the “guerrillas” are hard to beat, and small workshops do not bear any environmental costs.

Talking about the recycling of waste batteries, Ma Yonggang has a deep understanding of the allure of “price”. “Even if you pay 10 cents more per piece than others, it’s easy to collect right away.” He believes that in the waste battery recycling, “regular army” lost to “guerrillas”, recycling price is the main reason.

Why not raise the price? “You raise the price, guerrillas, especially the soil method of small lead refining enterprises will also mention, in short, he will be a little higher than you.” Ma Yonggang said, deep-seated reasons, is the “regular army” and “guerrillas” their respective recycling, processing costs are very different. He said: “Take a knife and axe, pry open the old battery, the most valuable lead plate out, plastic left behind, acid poured off, this is the processing of small workshops, the cost of production is almost negligible.”

So, what does the regular business do? Reporters in the Chunxing Alloy Group site saw, waste lead-acid batteries through the automatic grab bucket into the storage hopper, and then sent to the crusher, the resulting fragments were sent to the rear sequence sorting section. Then, the lead sludge in the debris was rinsed clean into the mixing tank, made of dehydrated lead sludge, the rest of the material continues to be processed. Along the production line, the reporter saw that the separator continuously separated the lead sludge, lead grids, plastic shells, partitions and other components and sent them to the silo respectively. The key point is that the whole crushing and sorting process is completely closed, no waste water discharge, some small workshops as “waste” and abandoned but seriously harmful to the environment, here the harmless treatment and resource utilization.

More than five or six thousand million yuan investment in the production line, but encountered small workshops to spoil the game, formal enterprise technology, process advantages but become a cost burden – Ma Yonggang said, their waste battery recycling price can only be set at 6800 yuan / ton or so, high company will have to pay, “more helpless, this price in the market is still very difficult to receive waste batteries.

According to the relevant national regulations, formal disposal enterprises must have waste acid treatment facilities, have flue gas desulfurization facilities, and the battery crushing and decomposition must be mechanized. Chen Feng believes that the formal enterprises thus take on more social responsibility, environmental responsibility. The small workshop just abandoned these responsibilities, “save” the cost of treatment, occupy the advantage of market price competition. “This is clearly unfair.”

How far is it to who produces and who recycles?

150 million electric car batteries looking for a good way out

According to the data released by the Ministry of Industry and Information Technology, in 2010, the number of electric bicycles in China reached 150 million. It is predicted that by the end of the 12th Five-Year Plan, the waste batteries of these electric bicycles alone will reach 6 million tons. This is not only a heavy environmental hazard, but also a valuable resource and wealth, and its return to scientific treatment can’t be delayed.

Experts believe that the business of recycling and disposing of used batteries has a certain public welfare attribute, and that the government should consider granting appropriate tax reductions or subsidies when non-enterprise reasons encounter insurmountable difficulties. Subsidy support policy can be considered for three to five years, when its recovery volume rises, the cost of natural reduction, competitiveness will come up. In July last year, Chunxing Group as the main investment in Pizhou Circular Economy Industrial Park entered the second batch of national “urban minerals” recovery and disposal of demonstration bases pre-selected list, all completed, the annual treatment of waste batteries can reach 1.2 million tons.

In the lead-acid battery industry, lead pollution from recycling is greater than pollution from the manufacturing process. It is suggested that the state should encourage the gradual establishment of a “who produces who recycles” system. In Jiangsu, several large battery manufacturers in the supply contract signed with the customer, has clearly required each other in the replacement of the disassembled old battery recycling, to have the processing qualification of manufacturers. At the same time, the provincial environmental protection department is considering raising the entry threshold and strengthening the qualification of disposal enterprises.

ShenZhen Topak New Energy Technology CO.LTD.

+86 13688963831 +86-0755-23768324

B2B@topakpower.com

Address: 26 Yingfeng 1st Road, Dalang Town, Dongguan City, Guangdong Province (Tuopai Industrial Park)

Hong Kong Branch: Topak International Co.,Limited.

Company address:FLAT/RM A, 9/F SILVERCORP INTERNATIONAL TOMER 707-713 NATHAN ROAD,MONGKOK KLN KOWLOON HONG KONG