12V 6Ah Lithium ion Battery Lifepo4 Battery

12V 10Ah Lithium ion Battery Lifepo4 Batteries

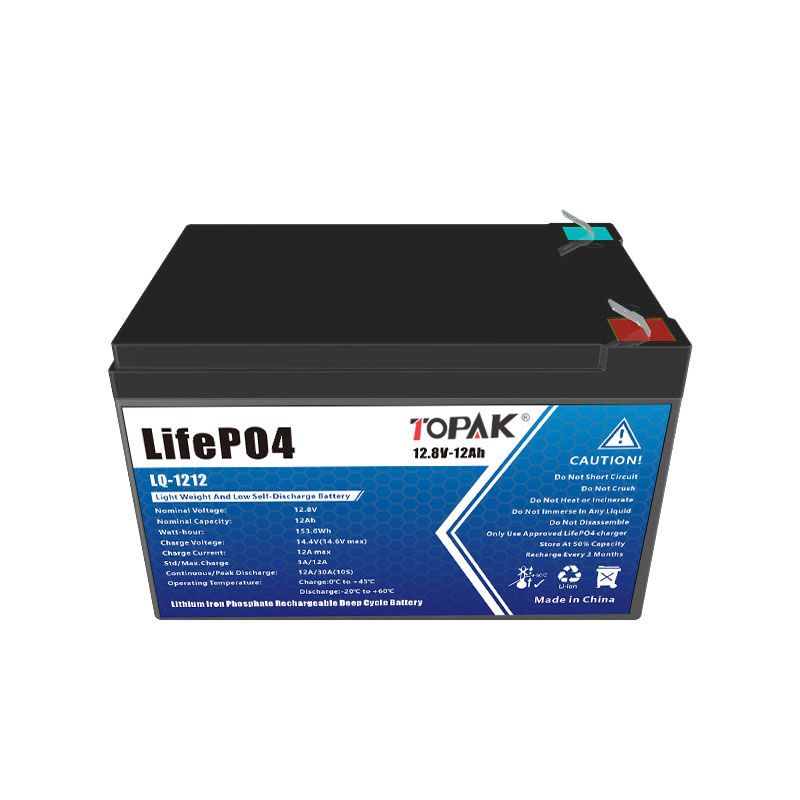

12V 12Ah LiFePO4 Lithium Iron Phosphate Battery

12V 18Ah Lifepo4 Lithium Battery Cell

12V 20Ah replacement Lead acid Lithium Battery

12V 36Ah Lithium Iron Phosphate Battery

24V 50Ah Lifepo4 Battery Lithium ion Battery

24V 100Ah lifepo4 iron batteries replacement lead acid lithium battery

24V 200Ah lifepo4 battery replacement Lead acid Lithium Battery

48V 50Ah Lithium Iron Phosphate Battery replacement Lead acid Lithium Battery

48V 100Ah lithium batteries replacement lead acid lithium battery

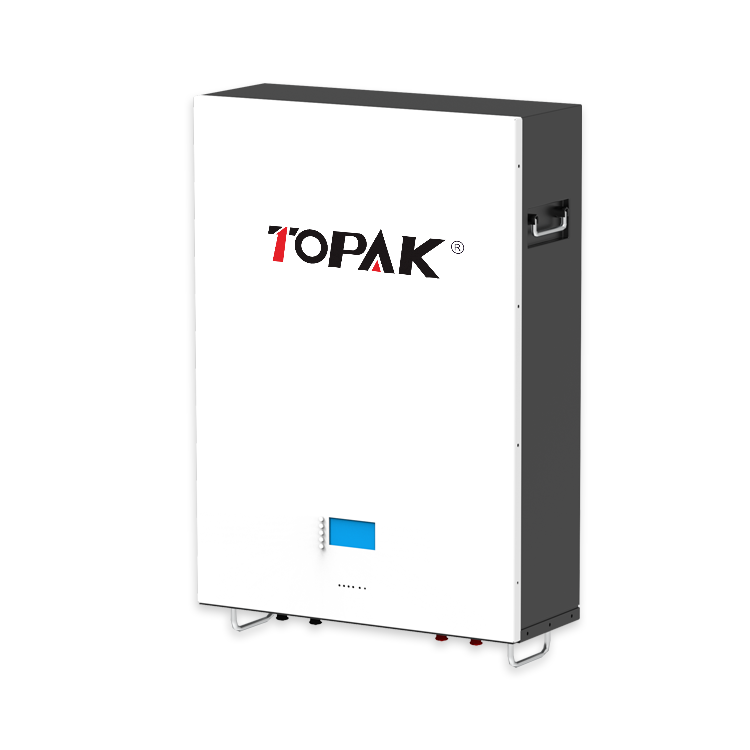

TOPAK 51.2V 300AH Vertical Home Energy Storage Battery

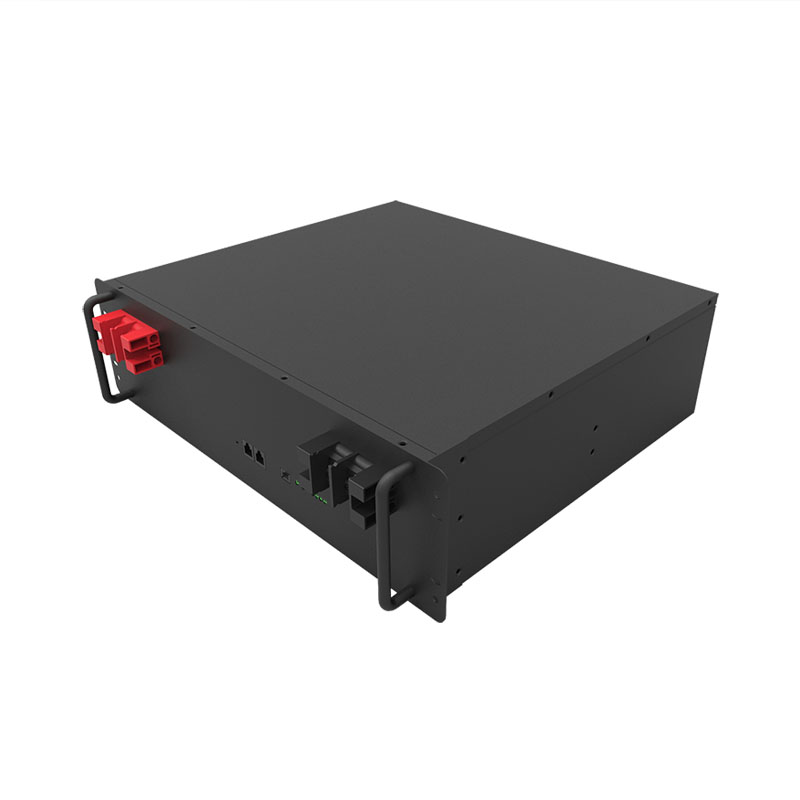

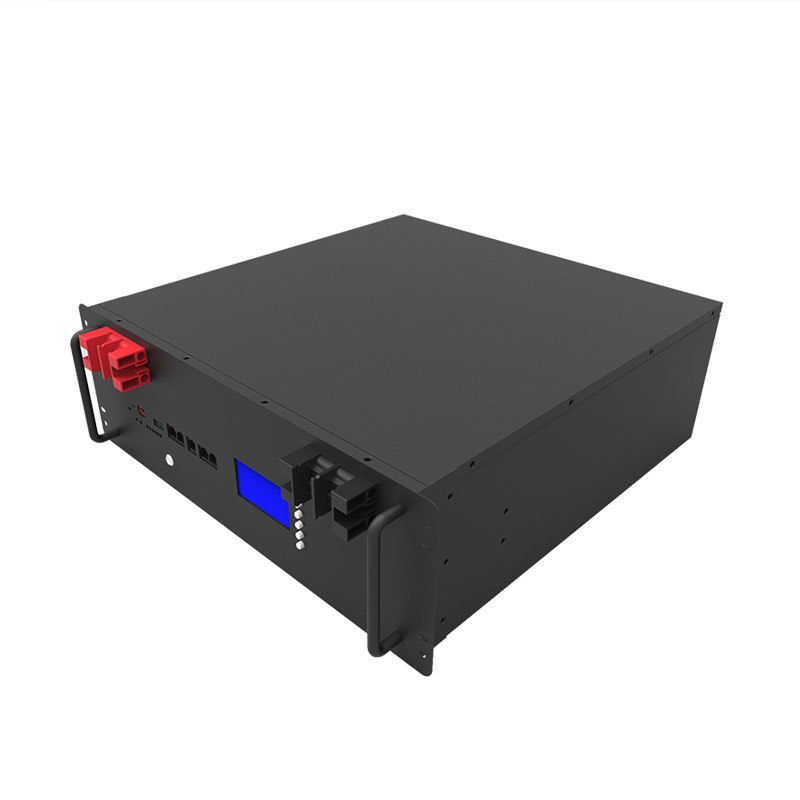

TOPAK 48V 100Ah Home Rack Mounted Energy Storage Batteries

TOPAK 51.2V 100Ah Stackable Battery Shunt able Solar Battery

TOPAK 24V 200Ah Solar Household Wall mounted Battery

48V 1000Ah household Photovoltaic energy storage split type machine

TOPAK 5KWA+5KWh Vertical Home Solar Inverter Energy Storage Integrated Machine Parallelable

384V 100Ah Backup power supply 38.4kWh UPS Data Center Power System

384V 50Ah Backup power supply 19.2kWh UPS Data Center Power System

192V 100Ah Backup power supply 19.2kWh UPS Data Center Power System

192V 50Ah Backup power supply 9.6kWh UPS Data Center Power System

224V 100Ah UPS Power System 22.4kW LiFePO4 Battery System

TOPAK 224V 30Ah Lithium ion UPS lifepo4 Battery 6.7KW UPS Backup

48V 150Ah tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

48V 100Ah(5U) tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

Topak tower energy stroage battery for backup power supply,home/hopital/bank/small business/base station use

Topak 48V 100Ah Lithium ion battery BMS Solar Energy Storage System Lifepo4 Battery

48V 200Ah tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

48V 100Ah(4U) tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

12V 100Ah Lifepo4 Battery Patent design lithium battery

TOPAK RV Lifepo4 Battery 12V 400ah Energy Storage Lithium iron Phosphate RV Battery

51.2V20AH Lithium battery for electric bicycle battery converter

10.8V2.1AH Massager lithium battery

29.6V7.5AH Reserve power supply lithium battery

64V100Ah electric tricycle lithium battery

Writer: TOPAKRelease time: 2023-10-19Page View: 58

In recent years, lithium battery customization has become increasingly popular among domestic and foreign customers, especially in certain specific industries such as electric vehicles, electric bicycles, drones, etc. The demand for lithium batteries has increased significantly, and the development of these industries has promoted the prosperity of the lithium battery customization market. So, what are the customization processes and precautions for lithium batteries? Let’s briefly discuss the customization process of TOPAK Lithium Battery:

Firstly, understand and confirm the customer’s needs

Before customization, it is necessary to understand the customer’s needs, including the environment in which the battery is used, the equipment used, the maximum discharge rate, the type, specifications, voltage, capacity, etc. of the battery, as well as the shell material and interface method of the battery. In general, we will ask customers to fill out a customer demand form, and then based on the customer’s needs, create a product specification plan for the customer to determine.

Secondly, select suitable spare parts

Based on the customer’s requirements and product specifications, our engineers choose suitable spare parts. If a suitable battery cell is selected: the battery cell is the core part of the battery, which directly affects the performance and safety of the battery; It is necessary to select according to customer needs and battery cell specifications to ensure that the quality and performance of the battery meet the requirements. Determine the size and weight of the battery based on customer needs, ensuring that the battery meets installation and usage requirements while ensuring that the size and weight of the battery meet customer needs. Only then will a technical agreement for the customer’s product be developed to ensure the standardization of the product required by the customer.

Thirdly, product production and performance testing

The production of products is based on the confirmed model performance in the technical agreement. Determine the charging and discharging characteristics of the battery: Based on the charging and discharging characteristics of the battery cell, determine the charging and discharging voltage, current, charging and discharging time and other parameters of the battery to ensure that it can charge and discharge normally without damaging the battery. The safety performance of batteries is crucial, and it is necessary to ensure that they do not experience safety issues such as leakage, explosion, or combustion. Therefore, it is necessary to choose high-quality and reliable battery cells, and take multiple safety measures during the design and manufacturing process of the battery, such as adding protective circuits and installing temperature sensors. After customization is completed, it is necessary to test and inspect the battery to ensure that its performance and safety meet the requirements.

Fourth, product delivery and after-sales service

Normally, during the delivery of the first batch of products, our engineers will confirm the performance of the products together with the customer, or conduct delivery confirmation when delivering samples. After delivery, we will provide comprehensive after-sales service, including battery repair, replacement, technical support, etc., to ensure that customers can use the battery normally and promptly solve any problems that may arise.

ShenZhen Topak New Energy Technology CO.LTD.

+86 15920229894

Phyllis@topakpower.com

Address: 26 Yingfeng 1st Road, Dalang Town, Dongguan City, Guangdong Province (Tuopai Industrial Park)

Copyright © 2019 Shenzhen topak new energy technology CO.LTD. 粤ICP备20054061号