12V 6Ah Lithium ion Battery Lifepo4 Battery

12V 10Ah Lithium ion Battery Lifepo4 Batteries

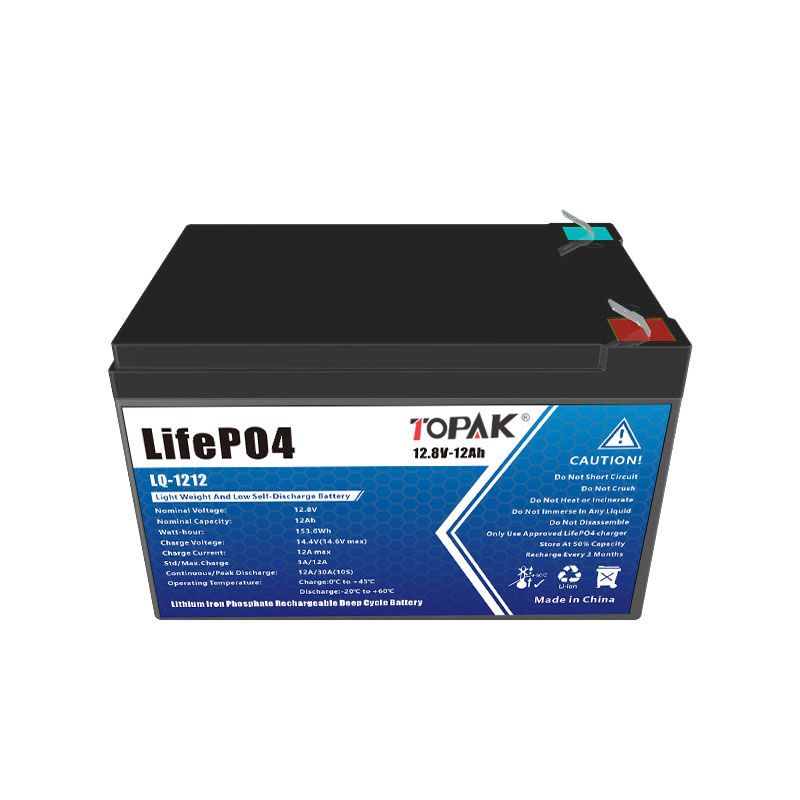

12V 12Ah LiFePO4 Lithium Iron Phosphate Battery

12V 18Ah Lifepo4 Lithium Battery Cell

12V 20Ah replacement Lead acid Lithium Battery

12V 36Ah Lithium Iron Phosphate Battery

24V 50Ah Lifepo4 Battery Lithium ion Battery

24V 100Ah lifepo4 iron batteries replacement lead acid lithium battery

24V 200Ah lifepo4 battery replacement Lead acid Lithium Battery

48V 50Ah Lithium Iron Phosphate Battery replacement Lead acid Lithium Battery

48V 100Ah lithium batteries replacement lead acid lithium battery

TOPAK 51.2V 300AH Vertical Home Energy Storage Battery

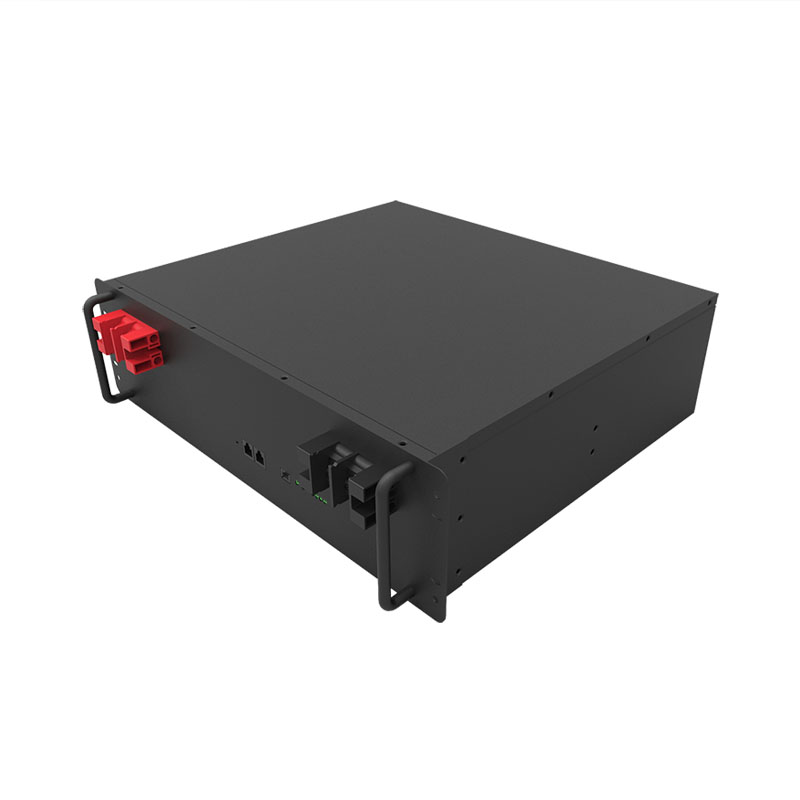

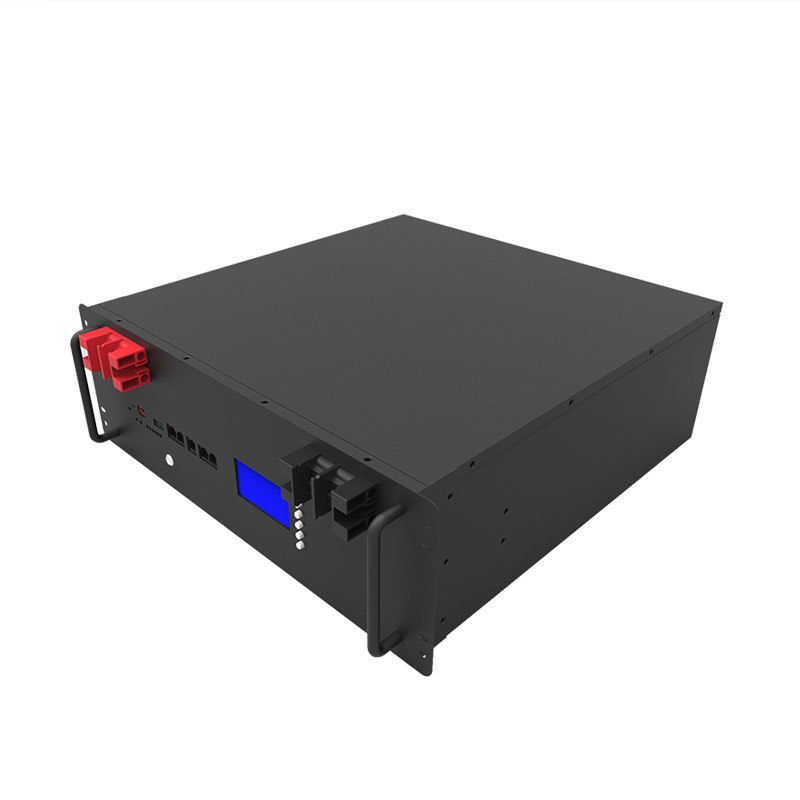

TOPAK 48V 100Ah Home Rack Mounted Energy Storage Batteries

TOPAK 51.2V 100Ah Stackable Battery Shunt able Solar Battery

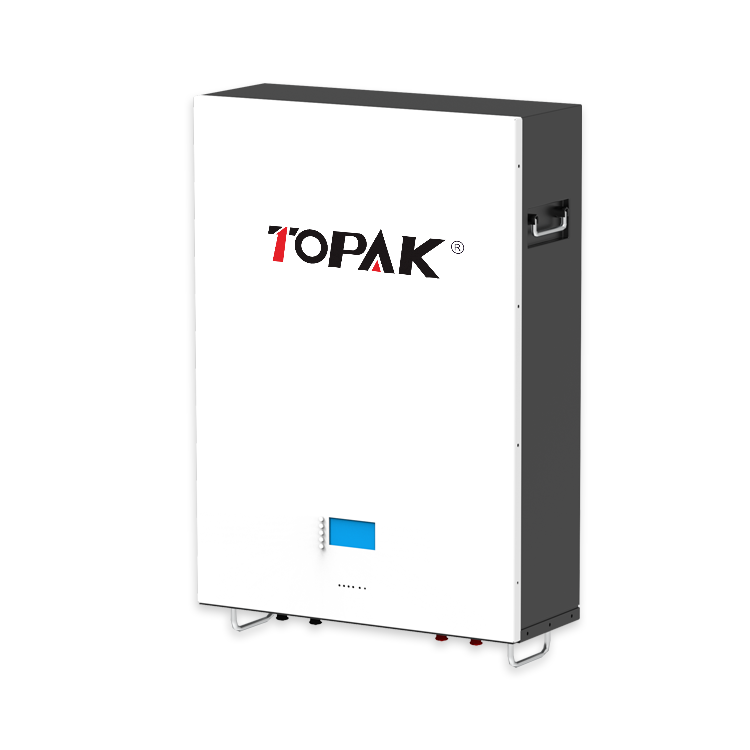

TOPAK 24V 200Ah Solar Household Wall mounted Battery

48V 1000Ah household Photovoltaic energy storage split type machine

TOPAK 5KWA+5KWh Vertical Home Solar Inverter Energy Storage Integrated Machine Parallelable

384V 100Ah Backup power supply 38.4kWh UPS Data Center Power System

384V 50Ah Backup power supply 19.2kWh UPS Data Center Power System

192V 100Ah Backup power supply 19.2kWh UPS Data Center Power System

192V 50Ah Backup power supply 9.6kWh UPS Data Center Power System

224V 100Ah UPS Power System 22.4kW LiFePO4 Battery System

TOPAK 224V 30Ah Lithium ion UPS lifepo4 Battery 6.7KW UPS Backup

48V 150Ah tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

48V 100Ah(5U) tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

Topak tower energy stroage battery for backup power supply,home/hopital/bank/small business/base station use

Topak 48V 100Ah Lithium ion battery BMS Solar Energy Storage System Lifepo4 Battery

48V 200Ah tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

48V 100Ah(4U) tower energy stroage battery ofr backup power supply,home/hopital/bank/small business/base station use

12V 100Ah Lifepo4 Battery Patent design lithium battery

TOPAK RV Lifepo4 Battery 12V 400ah Energy Storage Lithium iron Phosphate RV Battery

51.2V20AH Lithium battery for electric bicycle battery converter

10.8V2.1AH Massager lithium battery

29.6V7.5AH Reserve power supply lithium battery

64V100Ah electric tricycle lithium battery

Writer: TOPAKRelease time: 2019-06-12Page View: 652

According to statistics, the sales of new energy vehicles in March this year, year-on-year growth rate of 100.9%, while the retail of traditional fuel vehicles fell by 15.0% year-on-year. However, there are still some concerns about new energy vehicles, including the problem of battery degradation at low temperatures, which should be considered by consumers.

According to the test, under the simulated low-speed urban road conditions, -7℃ outside temperature and 20~22℃ inside temperature, the actual range is less than half of the nominal range. The simulated conditions of the test are harsh, but more suitable for winter driving scenarios, which shows that in the winter low temperature environment, the actual range of new energy vehicles (especially pure electric vehicles) will be greatly reduced, which will also have a greater impact on the driver’s experience.

The lithium battery, for example, which is widely used in new energy vehicles, has five main structural parts: positive electrode, negative electrode, electrolyte, separator, shell and electrode leads. In the winter low temperature environment, the viscosity of the electrolyte increases or even partially solidified, and the compatibility between the negative electrode and the diaphragm deteriorates, resulting in a decrease in battery activity, battery capacity and charge and discharge efficiency, resulting in the attenuation of the battery of the new energy vehicle.

In order to cope with this problem, most car companies are committed to optimizing the battery management system (BMS), in the low temperature environment, part of the electricity into heat energy, heating the entire battery pack, to some extent to improve the problem of low temperature battery degradation. In winter, it is recommended that consumers get into the habit of turning on the heating and air conditioning before driving and charging, which can raise the temperature of the battery itself to get higher mileage and charging efficiency.

ShenZhen Topak New Energy Technology CO.LTD.

+86 13688963831

B2B@topakpower.com

Address: 26 Yingfeng 1st Road, Dalang Town, Dongguan City, Guangdong Province (Tuopai Industrial Park)

Copyright © 2019 Shenzhen topak new energy technology CO.LTD. 粤ICP备20054061号